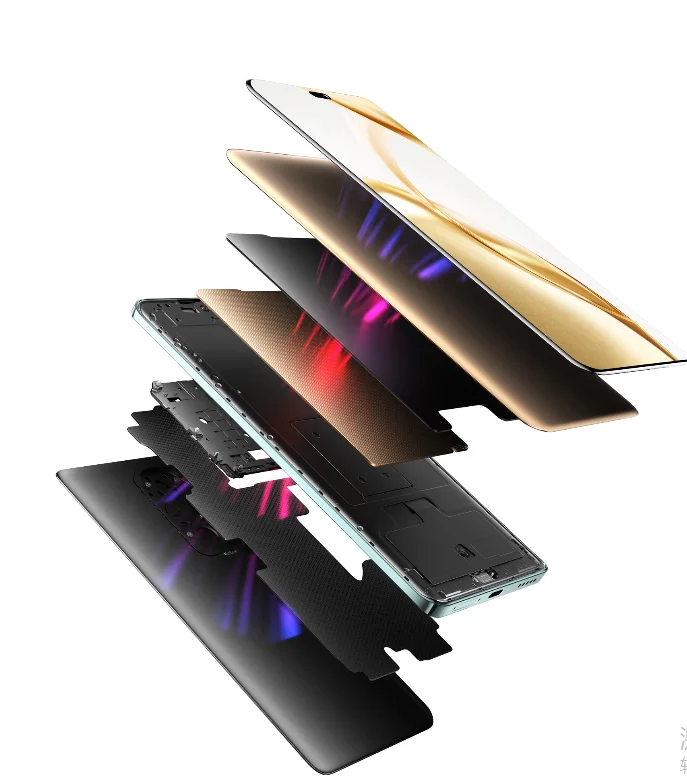

One way that businesses can improve their operations during peak seasons is by implementing a warehouse management system. This technology can help optimize the number of items in stock, speed up the way orders are filled, and improve the warehouse’s overall efficiency. By using real-time data and analytics, businesses can make informed decisions about staffing, resource allocation, and inventory management.

1. Would’ve

Hindsight is 20/20, and it’s easy to look back and say what could have been done differently. Here are some common “would’ve” scenarios that businesses may face after peak season:

- Would’ve hired more staff: One of the most common issues businesses face during peak season is not having enough staff to handle the increased workload. Looking back, it may have been beneficial to hire more staff or even bring in temporary workers to handle the increased demand.

- Would’ve increased inventory: Running out of stock during peak season can lead to dissatisfied customers and lost revenue. In hindsight, it may have been beneficial to increase inventory levels to avoid stockouts.

- Would’ve streamlined operations: Peak season can put a strain on operations, and it’s essential to have efficient processes in place to handle the increased workload. Looking back, businesses may identify areas where operations could have been streamlined, such as optimizing warehouse layout or improving order fulfillment processes.

2. Should’ve

While businesses can’t change the past, they can take action based on what they’ve learned during peak season. Here are some common “should’ve” scenarios that businesses may consider for future peak seasons:

- Should’ve implemented automation: Implementing automation can improve operational efficiency and reduce errors. For example, using a warehouse management system can help streamline inventory management and order fulfillment processes.

- Should’ve optimized staffing: To handle peak season demand, businesses should optimize staffing levels by hiring temporary workers or implementing flexible scheduling options.

- Should’ve focused on customer experience: Peak season is an excellent opportunity to provide exceptional customer service and build brand loyalty. Businesses should focus on providing a seamless customer experience, such as offering free shipping or providing proactive communication about the order status.

3. CAN:

The end of peak season is the perfect time for businesses to plan and prepare for future peak seasons. Here are some things businesses can do to prepare for future peak seasons:

- CAN implement a warehouse management system: A warehouse management system can help businesses optimize inventory management and streamline order fulfillment processes.

- CAN invest in employee training: Training employees on new technology or processes can help improve operational efficiency and reduce errors.

- CAN plan for contingencies: Businesses should have a contingency plan in place to handle unexpected situations, such as a sudden surge in demand or a natural disaster.

4. Conduct a Post-Season Review

Before preparing for future peak seasons, businesses should take the time to conduct a thorough review of the previous peak season. As part of this review, sales data, customer feedback, employee feedback, and operational data should all be looked at to find ways to improve.

By looking at sales data, businesses can find trends in what customers want, which can help them decide how to manage their inventory and staff. Customer feedback can show where a business may have failed to meet customer expectations, such as in how quickly orders are filled or how many products are available.

5. Optimize Inventory Management

Running out of stock during peak season can be a significant issue for businesses, leading to lost sales and dissatisfied customers. To avoid stockouts, businesses should optimize their inventory management processes. This could mean adding more inventories, using a just-in-time inventory system, or using software to manage inventory.

6. Develop a Contingency Plan

Preparing for unexpected events is crucial for businesses during peak season. Having a backup plan can help a business get ready for things like sudden increases in demand, natural disasters, or problems in the supply chain. A contingency plan should list what to do in these situations, such as alternative suppliers, plans for backup staffing, and ways to communicate.

7. Train Employees

Employee training is essential for ensuring operational efficiency and reducing errors during peak season. Businesses should think about giving their employees training on new technology or processes, customer service, and safety rules to make sure they are ready for the busy season. The use of Deposco or any other WMS can help in this regard.

8. Focus on Customer Experience

Providing exceptional customer service is key to building brand loyalty and ensuring repeat business. During peak season, businesses should focus on giving customers a smooth experience. They could do this by offering free shipping, keeping customers informed about the status of their orders, or starting a loyalty program.

Wrapping up

Peak season can be both an exciting and stressful time for businesses. But looking at the past and finding ways to make things better can help businesses get ready for future busy times. Businesses can handle peak season with confidence and success if they use new technology, make sure they have enough staff and focus on giving great customer service.