Seaside entertainment projects can be a fantastic investment opportunity for entrepreneurs. However, before embarking on such ventures, it’s vital to understand the legal and regulatory considerations that come with the territory. Zoning, permits, and environmental compliance are three key areas that require careful attention to ensure project success.

Zoning Regulations

Zoning regulations define the allowable use of the land for certain activities, including commercial and recreational ventures. When it comes to seaside entertainment projects, zoning regulations vary by location, and it’s crucial to know what is allowed. Before purchasing or leasing land to build a floating boat dock, conduct thorough research on the local zoning regulations. Some areas may not permit floating docks directly on the shoreline, while others may require setbacks from neighboring properties.

Permits and Licenses

Permits and licenses are necessary for any recreational project that involves the use of public waters. Before building a floating dock, it’s essential to obtain permits and licenses from the relevant authorities. These permits can vary depending on the location, the size of the project, and the intended use. For example, some jurisdictions require environmental studies, while others require engineering specifications. It’s crucial to work with a knowledgeable attorney to guide you through the process of obtaining the necessary permits and licenses.

Environmental Compliance

Seaside entertainment projects must adhere to strict environmental standards to avoid negative impacts on the environment. Concerns surrounding water quality, habitat preservation, and wildlife protection must be addressed during the project design phase. Sustainable materials, like plastic injection OEM technology, can play a significant role in ensuring that a project is environmentally responsible.

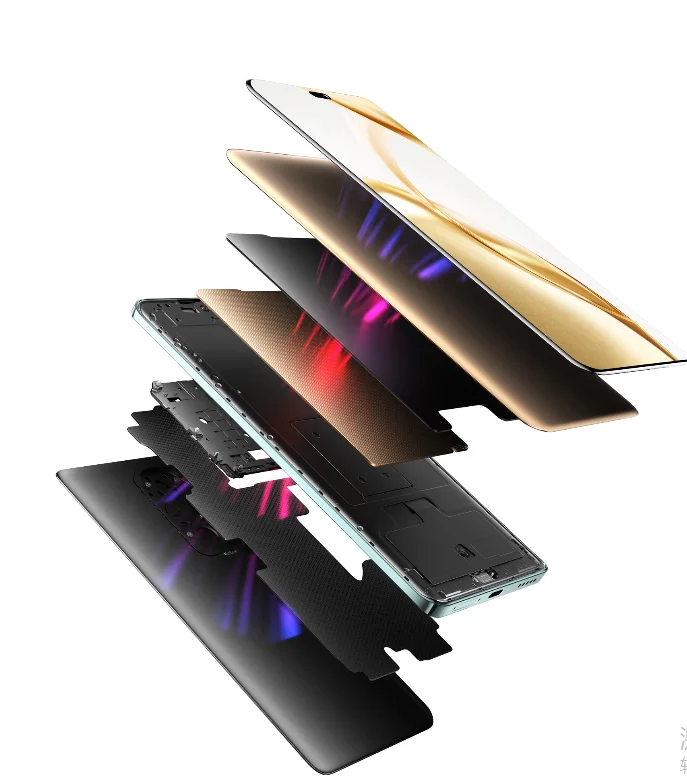

Using Plastic Injection OEM Technology for Environmental Compliance

Plastic injection OEM technology involves the use of custom molding processes to create durable and sustainable plastic parts. This process results in high-quality finished products that are ideal for use in seaside entertainment projects. Plastic injection OEM technology is especially useful for constructing floating boat docks as it can create durable, buoyant, and resistant materials that can withstand the water environment.

The Benefits of Plastic Injection OEM Technology for Floating Boat Docks

Plastic injection OEM technology provides an opportunity to build durable floating boat docks with minimal maintenance needs. The technology creates a seamless finish that eliminates surface irregularities, keeping the dock area smooth and safe. Additionally, the technology provides an opportunity to create custom-fit dock components that fit specific project needs. These parts can be designed to be resistant to UV rays, saltwater, and other elements, making them ideal for seaside environments.

Conclusion

Seaside entertainment projects, including floating boat docks, require thorough research and attention to legal and regulatory considerations. Zoning regulations, permits, and environmental compliance are crucial factors that must be considered before embarking on such ventures. Additionally, plastic injection OEM technology can play a crucial role in ensuring that a project is environmentally responsible and compliant. As such, by working with experienced attorneys and OEM plastic injection molding companies, entrepreneurs can build successful and compliant seaside entertainment projects.