Slip-ring connectors play a crucial role in facilitating the transmission of electrical signals and power between stationary and rotating components in various applications and industries. They enable continuous rotation while maintaining uninterrupted electrical connections. In this article, we will delve into the world of slip ring connectors, specifically focusing on DIY slip ring connectors and PCB slip rings, to explore their versatility and benefits.

Understanding DIY Slip Ring Connectors

DIY slip ring connectors are custom-made connectors that you can build yourself, tailored to your specific requirements. They offer several benefits, including:

Cost-effectiveness: Building a DIY slip ring connector can be more budget-friendly compared to purchasing pre-manufactured options. By sourcing the necessary components and materials, you can save on costs without compromising quality.

Customization: DIY slip ring connectors allow for customization according to your project’s unique specifications. You have control over the design, size, and configuration, ensuring a perfect fit for your application.

Flexibility: A DIY approach enables you to adapt the slip ring connector to suit your specific needs. You can choose the type and quality of materials, incorporate additional features, and modify the design as required.

DIY slip ring connectors find applications in a wide range of scenarios. Whether you’re a hobbyist working on a personal project or an engineer developing a prototype, a DIY approach provides the flexibility and creativity necessary to achieve your desired results. Many DIY enthusiasts have successfully built their own slip-ring connectors for applications such as rotating cameras, robotics, wind turbines, and more.

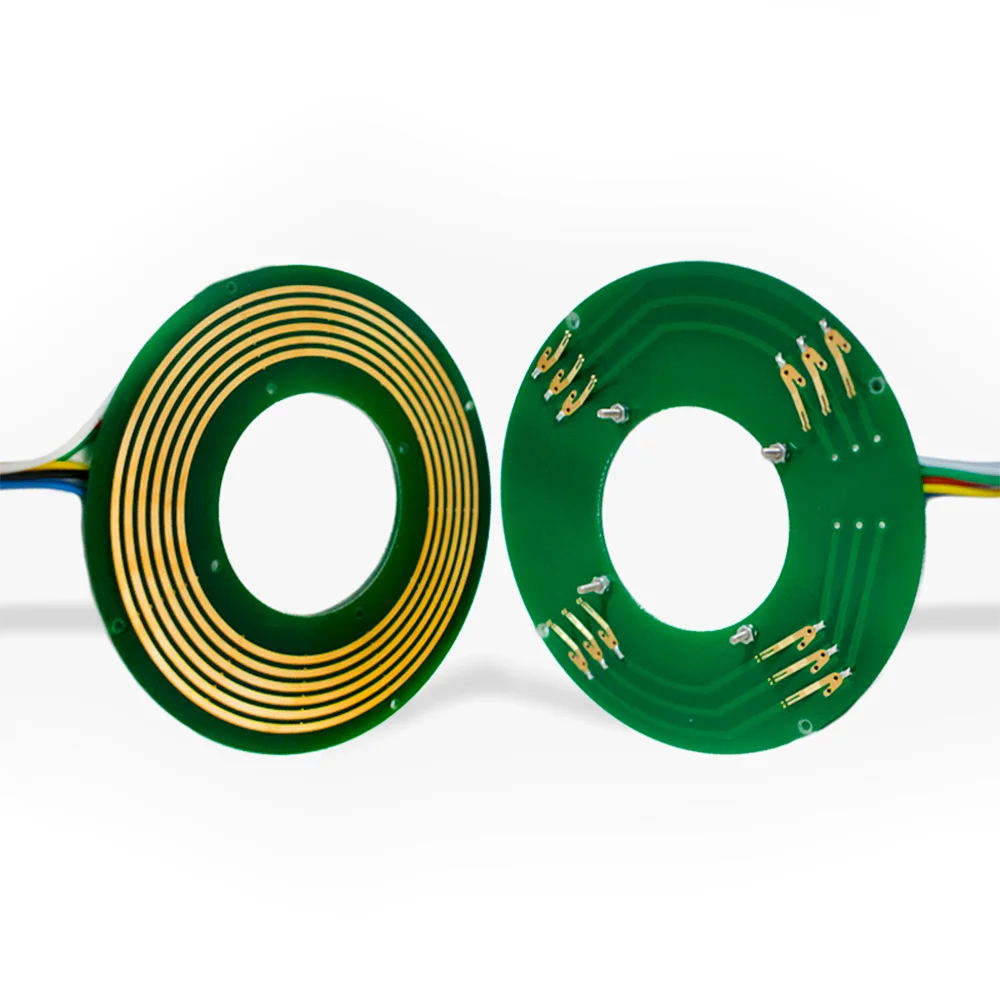

The Advantages of PCB Slip Ring

PCB slip rings, or printed circuit board slip rings, offer unique design characteristics that make them highly advantageous in various industries. These advantages include:

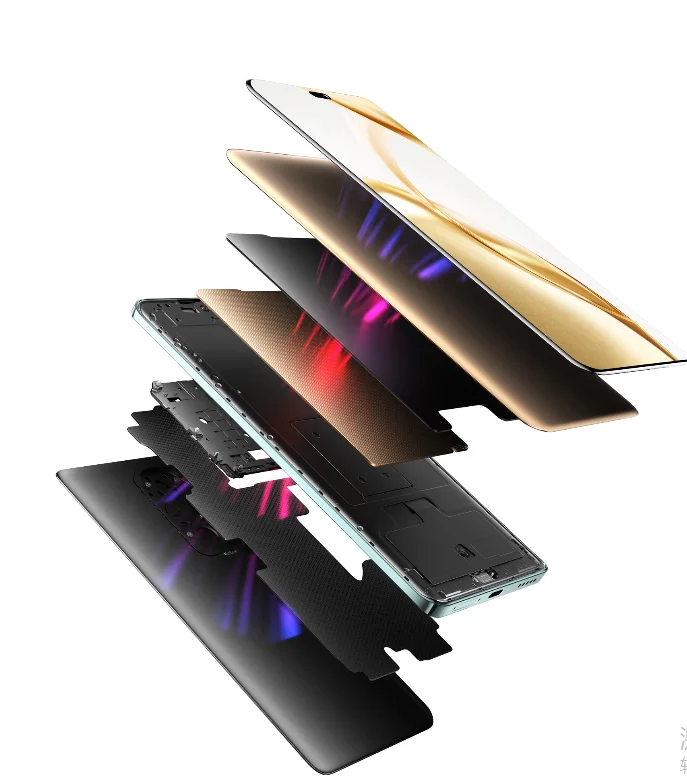

Compact Size: PCB slip rings are compact due to their integration of conductive tracks directly onto a printed circuit board. This feature is especially beneficial in applications where space is limited or weight restrictions apply.

High Signal Integrity: PCB slip rings provide excellent signal integrity and low electrical resistance. The conductive tracks on the PCB are carefully designed to minimize signal loss, interference, and noise, ensuring reliable transmission of signals and power.

Customizable Designs: With PCB slip rings, you have the freedom to customize the design and layout of the conductive tracks. This allows for specific signal routing, voltage compatibility, and incorporation of additional components to meet the requirements of your application.

PCB slip rings are widely used in industries such as aerospace, defense, robotics, medical devices, and automation. They excel in applications where compact size, high signal integrity, and customization are paramount.

DIY vs. Pre-manufactured PCB Slip Rings

When considering slip ring connectors, one must decide between a DIY approach or purchasing pre-manufactured PCB slip rings. Each option has its benefits and drawbacks, and several factors should be considered during the decision-making process, including:

Cost: DIY slip ring connectors can be more cost-effective since you have control over the components used and can potentially repurpose existing materials. However, pre-manufactured PCB slip rings often offer standardized pricing and may be more economical for larger-scale projects.

Customization: DIY slip ring connectors allow for extensive customization, accommodating specific requirements and modifications. Pre-manufactured PCB slip rings, on the other hand, typically come with predefined specifications and limited customization options.

Time Constraints: DIY slip ring connectors may require additional time for research, sourcing materials, and assembly. If time is a critical factor, pre-manufactured PCB slip rings offer the advantage of immediate availability and reduced assembly time.

To aid in the decision-making process, it can be helpful to examine case studies and testimonials from individuals who have chosen either the DIY or pre-manufactured route. Assessing real-world experiences can provide valuable insights into the benefits and limitations of each approach.

Conclusion

DIY slip ring connectors and PCB slip rings offer distinct advantages and flexibility in various applications. DIY slip ring connectors provide cost-effectiveness and customization options, making them suitable for personalized projects and specific requirements. PCB slip rings, with their compact size and high signal integrity, excel in industries where space constraints and reliable signal transmission are crucial.

When choosing between DIY slip ring connectors and pre-manufactured PCB slip rings, it is essential to evaluate your project’s needs, considering factors such as cost, customization, and time constraints. By carefully assessing your specific requirements and available resources, you can make an informed decision that best suits your application.

Remember, slip ring connectors play a vital role in maintaining seamless electrical connections in rotating systems, so it is crucial to prioritize the application’s requirements and choose the option that best aligns with your project’s goals. Whether you opt for a DIY approach or pre-manufactured PCB slip rings, the versatility and benefits of slip ring connectors ensure efficient and reliable electrical transmission in a wide range of applications.